SIMATIC RTLS - Real-Time Location System

Where are the goods?! Siemens will help you to localize it!

In the Siemens product range, it is the SINAMICS drives that are responsible for the smooth movement of articles in your plant. When it comes to localization and communication of moving vehicles and equipment, SIMATIC RTLS is the system responsible.

This system is a key element in the infrastructure of modern factories or warehouses. SIMATIC RTLS is responsible for providing information to robots or AGVs about the current situation in the production plant or logistics center thanks to its ability to locate the object with an accuracy of a few centimeters on the work surface. The signals sent by the transmitters are received by the RTLS system, which can then freely locate this or that object in the plant and transmit the status and location to intelligent logistics management systems or production sites.

SIMATIC RTLS features wireless communication using UWB technology, which operates in the frequency range of 3 to 7 GHz and uses 500 MHz bandwidth, eliminating the risk of interference between other systems in the plant. A further advantage of SIMATIC RTLS is the ease of installation and the possibility of expansion in case of extensions of the production area or warehouse.

The SIMATIC RTLS is able to determine the exact location of the containers with the goods, so that the goods (in a plant with extensive logistics infrastructure) do not change their position without the operator's knowledge. Continuous analysis of the situation on the shop floor allows to build optimal transport paths to avoid bottlenecks and transmit information messages to the control panel operated by the employee.

Another Siemens solution for identifying goods and various objects is the SIMATIC MV500 vision identification system. This system efficiently identifies barcodes and DataMatrix codes. In addition to barcode reading, the SIMATIC MV500 can read OCR text, recognize the shape of an object and verify the quality of a label.

In the case of the need to verify a large number of objects simultaneously, the RFID system (Radio Frequency Identification) will be invaluable. RFID systems can identify from a few individual products to hundreds of different types of goods in a package or on a pallet in a warehouse. Such identification is a very important aspect of functioning of modern manufacturing companies, where every piece of information about the location of the goods on the production line or in the warehouse allows large logistics companies or manufacturing giants to work without unnecessary downtime. In addition, when goods are shipped all over the world by different modes of transportation, tracking solutions from Siemens will help you find information about the goods and their location at any time.

Through the Siemens SCALANCE W device and the PROFINET protocol, dozens of devices in your plant can exchange information with each other allowing applications to run smoothly and quickly.

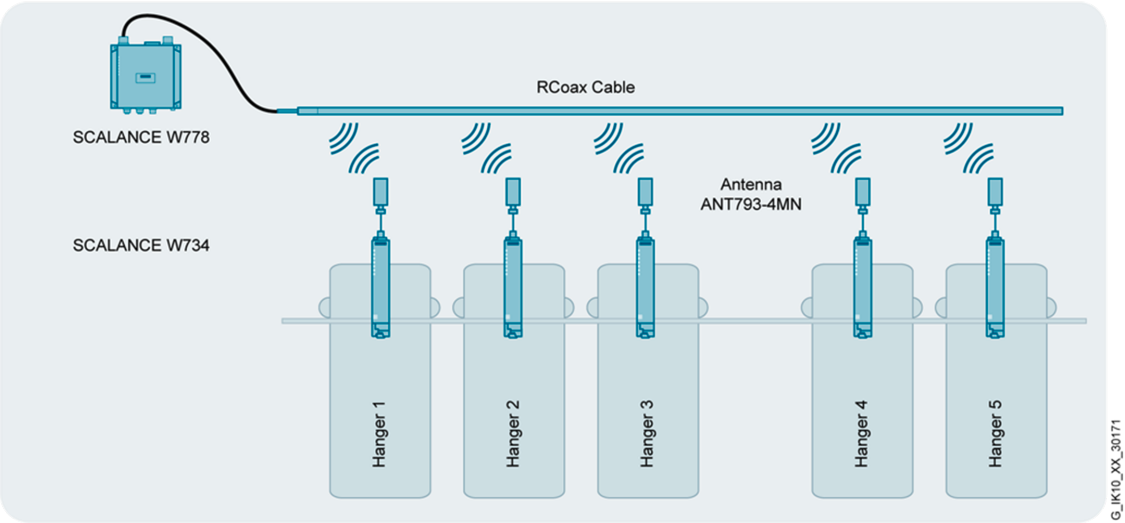

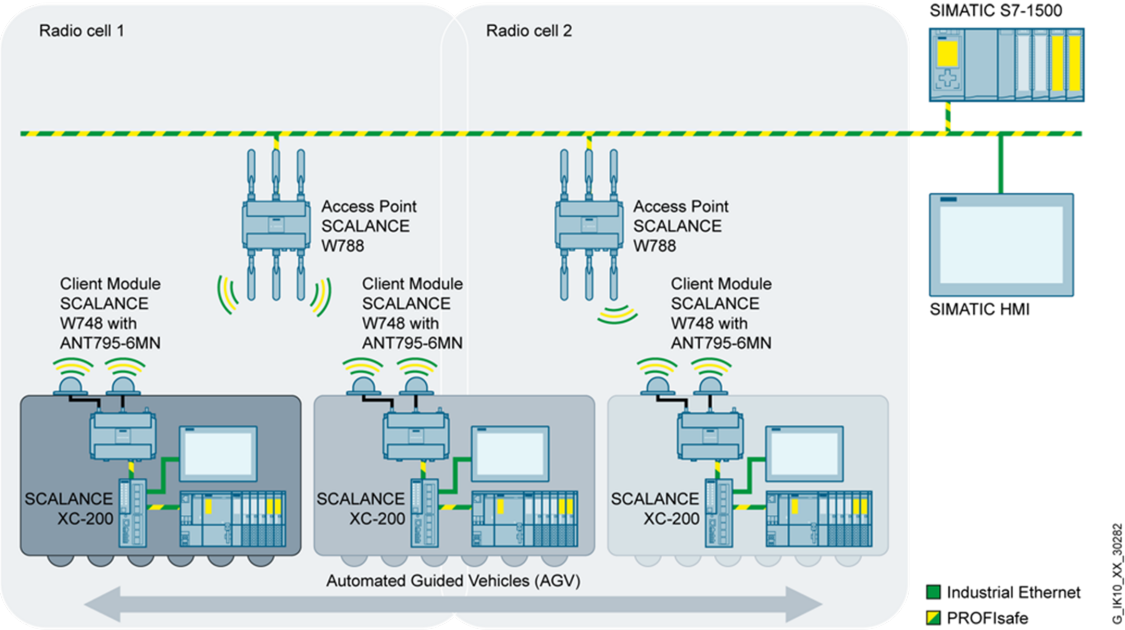

If we have situations where our goods are moving along a designated path in the application, SCALANCE W can use RCoax antennas to provide short range wireless data exchange. In this case, RCoax type antennas must be placed along the entire path of the goods and directly installed on the moving item. When using AGV-type mobile robots on the plant, data exchange is done via a wireless access point system. Regardless of the chosen option for monitoring and expansion of the intralogistics network, the entire system is based on the Industrial Ethernet/PROFINET communication standard.

In large plants, where every second of work is very important, even a small delay of even one package can lead to serious problems and stop the entire production or warehouse line. In these cases, data exchange on PROFINET may not be sufficient due to the tight time frame. In this case, Siemens offers the SCALANCE W-700 module, which features the Industrial Point Coordination Function (iPCF) and the Point Coordination Function Management Channel (iPCF-MC). These solutions guarantee fast switching between individual access points, thus eliminating delays in information exchange. This solution allows for smooth operation of the entire intralogistics line.

Here are some reference numbers of SCALANCE system components:

SCALANCE access point for cabinets:

SCALANCE W774 RJ45 for cabinets:

6GK5774-1FX00-0AC0

SCALANCE W788 RJ45 for control cabinets:

6GK5788-1FC00-0AA0

6GK5788-2FC00-0AC0

Also in our offer you may find different accessories, RCoax antenas, cables etc.

Find out more about our offer by visiting the tabs with Siemens-PLC and Schneider-PLC products. If the product you are looking for is not on our website or you have additional questions, please contact us at inquiry@plc-drives.com or directly at our representatives (addresses available in the "CONTACT" tab). We are able to supply you with all Siemens and Schneider PLC products, including those already withdrawn from production. Check our offer!