SIMATIC S7-300 Controller – application, construction, CPU and programming

SIMATIC S7-300 Controller - application, construction, CPU and programming

The SIMATIC S7-300 is the most popular and widely used PLC controller in the industry. It's a universal industrial automation platform that allows the construction of distributed and autonomous control systems using communication networks. With the PROFIBUS and Ethernet/PROFINET interfaces, the SIMATIC S7-300 enables the creation of coherent and integrated production management systems. Its modularity and a broad selection of available modules provide the capability to create almost any control system - central or distributed. A notable feature is the arbitrary order of modules in the controller cassette. The controller uses an external MMC card as persistent memory for programs and data. A unique characteristic of the CPU is its maintenance-free operation and it also does not require a battery. The MMC card not only stores source files but also technical documentation and allows for software updates. It can also perform measurement functions and store various recipes. On offer are specialized modules for managing electric drives or security systems (Safety Integrated technology) as well as SIPLUS versions adapted for extreme temperatures and demanding environmental conditions.

The SIMATIC S7-300 controller has been applied across a broad spectrum of industrial sectors such as:

- Chemical industry,

- Machine industry,

- Automotive,

- Food processing,

- Packaging machines/specialized machines,

- Mass production,

- Process engineering, which includes water treatment plants and wastewater treatment facilities,

- Plastic processing,

- Construction automation.

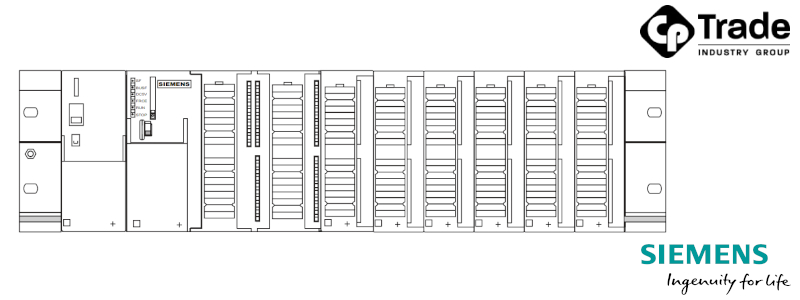

Construction of SIMATIC S7-300

The SIMATIC S7-300 controller consists of three main components: a power supply (PS), a processor (CPU) and input/output modules (SM). Regardless of the order, modules can be freely attached to the CPU. Individual components are mounted on a universal DIN rail, which simultaneously improves the electromagnetic compatibility of the controller and provides shielding for the communication bus. Modules are connected via a bus connector, which is an integral part of every module.

A maximum of 8 input/output modules can be placed in one cassette, with one CPU capable of handling up to 32 modules (distributed across 4 cassettes). Interface modules IM 365 or IM 360/361 enable communication between cassettes. Depending on the chosen module, the distance between cassettes can reach up to 10 meters. In a single cassette configuration (CC), the maximum number of inputs/outputs is 256, while in multi-cassette configurations it's 1024. Using the PROFIBUS system, the CPU can handle up to 65,536 points.

The central units of the SIMATIC S7-300 differ in memory, computational power and communication resources. A rich selection of CPUs allows for the use of S7-300 in simple applications as well as complex control systems. Their compact construction and small size are their distinguishing marks - standard CPU units have a width of 40 mm.

CPU units also come in special variants designed for multi-axis drive systems. They are distinguished by built-in functions, such as:

- Built-in PID control functions,

- Rapid counting and frequency measurements with access to hardware counters,

- Positioning using built-in SFB functions and standard MICROMASTER drives.

Selecting a CPU for the S7-300 Controller - summary

When choosing components for a controller, various factors must be considered, such as the capacity of the required working memory, the speed of the controller's operation, its mode of functioning (standalone or distributed) and the number of analog and binary inputs/outputs. Equally crucial is the potential for additional communication, especially when using Profibus/Profinet interfaces. The core of the controller configuration is the Central Processing Unit (CPU). For the S7-300 controller, four main categories of CPU can be distinguished.

- The first of these are the standard CPUs (6 units) which, depending on the needs, offer MPI/Profibus, DP/Profinet interfaces and can optionally support isochronous mode in Profibus. These are compact units with a width of 40mm.

- The next category includes FailSafe CPU units (5 units). They have an additional safety feature - the Profisafe profile which allows for the implementation of special safety circuits.

- The third group comprises compact CPUs (6 units). Depending on the model, they have built-in binary inputs/outputs or a combination of binary and analog. They are distinguished by additional functions such as counting, closed-loop control, frequency measurement, pulse width modulation or positioning.

- The last category is the technological CPUs (2 units). They are adapted to control advanced drive systems and have an additional DP (Drive) communication interface. It's worth noting that both compact and technological CPUs do not have an integrated Profinet interface.

SIMATIC S7-300 Controllers - additional information

MMC Memory Cards

The MMC memory card is used for saving and storing the program and other data in the CPU unit. Its use simplifies the servicing and expansion of the automation system. In addition to the main program, the entire project created in the SIMATIC Manager can also be stored, which includes symbolic names of variables and comments on individual steps. When more advanced programming languages are used, the card can store not only the source code but also the original project with a graphical representation of the program created in S7-HiGRAPH. As a result, the controller does not require an additional external backup battery, which translates into lower operating costs.

Programming

The S7-300 series controllers are programmed using the STEP 7 or STEP 7 Lite packages. These toolsets allow for intuitive and efficient use of all controller functionalities. Both STEP 7 and STEP 7 Lite provide comprehensive tools for creating a control project - from designing the hardware configuration, through implementing the control algorithm and launching the system, to diagnostics and servicing of the controller.

STEP 7 LITE

STEP 7 Lite is an economical software solution designed for creating stand-alone applications based on the S7-300 controller, which do not engage function modules (FM) or communication (CP). Its main advantage is its intuitive handling and the ability to design applications efficiently. Unlike the more extensive STEP 7, the Lite version is not compatible with additional packages like Engineering Tools. However, programs created in STEP 7 Lite can be modified and edited in the full version of STEP 7.

STEP 7

STEP 7 is used to design advanced control applications that are relatively extensive and complicated. It is particularly useful in situations where higher-order programming languages and functio and communication modules are required. This software works with additional packages like Engineering Tools, ensuring greater flexibility and extensive possibilities in control system design.

Engineering Tools

The Engineering Tools software packages provide advanced tools that allow programming controllers in functionally oriented languages. They are used for designing complex control systems that might require more memory space in the controller. Each of these tools has unique features and applications, making Engineering Tools a versatile package for programming complex control applications. This family includes:

- S7-SCL (Structured Control Language) - A high-level language based on the PASCAL structure, allowing for more advanced programming functions.

- S7-GRAPH - A graphical programming language dedicated to sequential controls, facilitating the visualization and tracing of logical process flows.

- S7-HiGRAPH - A language that enables a graphical representation of both sequential and asynchronous control processes. It allows for the creation of status diagrams, providing a complete picture of the operation of the S7/C7 controller.

CFC (Continuous Function Chart) - A high-level language that enables the graphical representation of processes in the form of a technological plan.

Find out more about our offer by visiting the tabs with Siemens-PLC and Schneider-PLC products. If the product you are looking for is not on our website or you have additional questions, please contact us at inquiry@plc-drives.com or directly at our representatives (addresses available in the "Contact" tab). We are able to supply you with all Siemens and Schneider PLC products, including those already withdrawn from production. Check our offer!